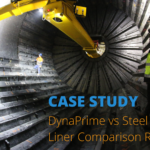

DynaPrime solution reduces the ramp up of SAG mills and increases efficiency

40-foot SAG Mill improves grinding and increases TPH over a shorter period of time.

Víctor Moreno, Business Development Manager of Tega Industries Chile, describes the results after the installation of DynaPrime in a 40-foot SAG mill. He explains that, by maintaining an appropriate condition of operational variables and considering only speed as a study variable, the highest operational efficiency and grinding ability is achieved in SAG mills when they reach speeds from 74% to 78% with respect to their critical speed. “However, when the liners are new, it is not possible to accelerate to those levels, as the impact generates cracks or energy absorption that later transforms into fractures of the mill liners. The period of time in which the mill takes to reach this desired speed can vary between 20 to 40 days or more, which is called ramp up ”, he explains.

He asserts that “our DynaPrime (rubber-metal) mill liners allowed a 40 foot mill to quickly approach the desired speed (74% to 78% Vc), thereby improving grinding and consequently increasing TPH in a shorter period of time. In other words, we contribute to reducing the ramp up period”.

Challenges overcome

DynaPrime, a rubber-metal composite mill liner, has a high impact absorption capacity without fracturing compared to steel mill liners, due to the combination of three main factors;

fracturing compared to steel mill liners, due to the combination of three main factors;

1) the wear resistance of rolled steel

2) the cushioning it provides; the rubber functioning as an energy sink and

3) the pyramid configuration of the DynaPrime steel inserts.

This provides adequate compressive rigidity and high longitudinal displacement capacity, allowing the impact energies to be dissipated and not directly transmitted to the mill shell or bolts.

How was the application process? “Our client evaluated us installing our mill liners in a 40 foot SAG mill and in the most aggressive mill sector, with the highest levels of impact. This application benchmarked service life and the ability to withstand impact without fracturing. At the beginning of this campaign, the customer’s expert control system was calibrated to perceive the impact (by sound) on steel liners and, as it did not detect the impacts that occurred on the DynaPrime liner, the mill was accelerated to speeds close to 76 % Vc, a scenario in which our mill liners endured without complications.

Moreno affirms that “the initial test had the purpose of increasing the reliability and durability of our mill liners, which was successfully demonstrated, but beyond that, the reduction of the ramp up period became a very positive “collateral” result that allowed the client to maximise the tonnage of the campaign therefore obtaining a much higher profit than initially expected”, he adds.

Moreno affirms that “the initial test had the purpose of increasing the reliability and durability of our mill liners, which was successfully demonstrated, but beyond that, the reduction of the ramp up period became a very positive “collateral” result that allowed the client to maximise the tonnage of the campaign therefore obtaining a much higher profit than initially expected”, he adds.

For more information on the DynaPrime product click here.